Share With

- The Importance of Packaging in Natural Stone Export

Despite their hardness, building stones are vulnerable to impact, vibration, and moisture. Precision cutting, surface finishing, and processing turn these materials into high-value products that must be carefully protected during transport and export. For this reason, standardized and professional packaging plays a vital role in preserving stone quality and ensuring customer satisfaction.

- Packing

Wooden Bundle

Wooden Bundle

A wooden bundle is one of the most common and secure methods for packing stone slabs, marble, and other sensitive products. The combination of hardwood and softwood provides an ideal balance of strength and flexibility.

Technical Specifications

- Type of wood:

- Base and supports: hardwood, 60 mm thick

- Dimensions:

- Manufactured to match the exact size of the slabs

- Standard height from ground:

- 80 mm clearance for forklift handling

- Recyclable: Yes

- Cost:

- More expensive than an iron bundle

Loading & Handling

- Suitable for marble, limestone, travertine slabs and other delicate stones

- After loading into the container, the bundle is fully lashed and braced to prevent any movement during transport

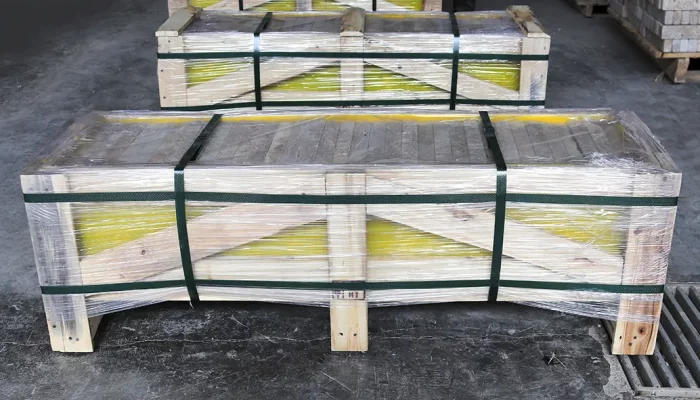

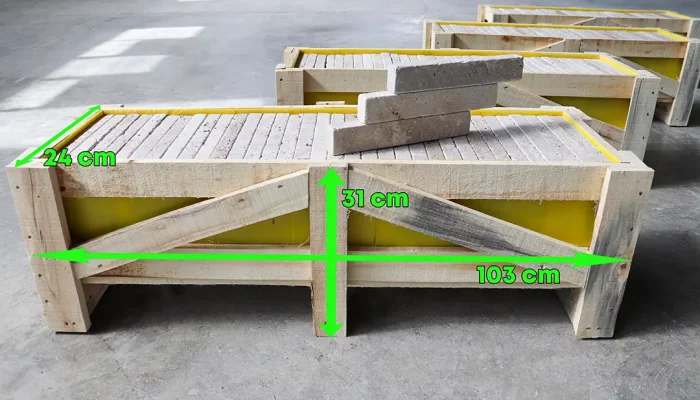

Wooden Crate

Wooden Crate

Wooden crates are used for packing tiles, small-size stones, sensitive products, and export consignments.

Technical Specifications

- Type of wood:

- Green (wet) wood for higher strength; after packing, the wood shrinks slightly and clamps the load more tightly

- Option to use dry wood on request, which is cheaper but provides lower structural strength

- Wood thickness:

- Base: 20 mm

- Walls: 17–20 mm

- Load capacity:

- Maximum: up to 2 tons

- Recommended loading: 1.5–1.7 tons

- Standard height from ground:

- 80 mm for easy forklift access

- Recyclable: Yes

Packing Process

- A 20 mm EPS foam sheet is laid on the base of the crate

- Tiles or small stones are stacked inside and then secured with strapping

- Finally, the crate is wrapped with shrink film or stretch film

- For smaller stone pieces, internal corrugated plastic sheets (carton-plast) are recommended to reinforce the walls and improve stability

Wooden Pallet

Wooden Pallet

- A wooden pallet is an economical and practical solution for packing tiles, steps, massive stones, and budget-oriented products.

Technical Specifications

- Standard height:

- 80 mm, designed for forklift handling

- Load capacity:

- Up to 2 tons

- Wood quality:

- Base: high-quality wood, 20 mm thick

- Recyclable: Yes

Packing Process

- Corners are reinforced with cardboard angle protectors

- The load is fully wrapped with stretch film or protective plastic

- Final strapping is applied to prevent movement during handling and transport

Carton Box (for Mosaic Tiles)

Carton Box (for Mosaic Tiles)

Carton boxes are the standard, lightweight packaging solution for stone mosaic tiles. This type of packaging is dedicated exclusively to mosaic products.

Specifications & Application

- Each carton contains 10 sheets of mosaic

- Designed specifically for delicate, small-format pieces

- Carton dimensions are adjusted according to the material, thickness, and tile size

- Recyclable: Yes

Benefits

- Prevents scratching between mosaic sheets

- Reduces the risk of breakage during handling and transport

- Allows neat stacking on pallets

- Ideal for export shipments and long-term storage

Final Packaging

- Cartons are stacked on wooden or metal pallets

- The palletized load is secured with stretch film or shrink wrap

- Suitable for safe loading in containers and trailers

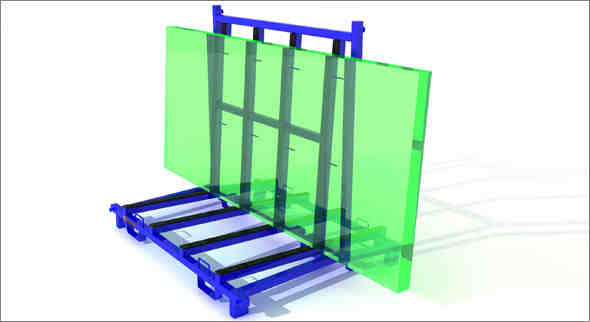

Iron Bundle

Iron Bundle

The iron bundle is one of the strongest packing systems for slabs and long stone pieces (Long Slabs) and is widely used in heavy-duty and project-based shipments.

Technical Specifications

- Structure:

- Steel box sections (HSS) 40×40 mm or 40×80 mm

- Base:

- Reinforced wooden planks

- Walls:

- Foam sheets or thin wooden boards to protect against impact and scratching

- Standard height from ground:

- 80 mm for forklift handling

- Recyclable: Yes

- Price and weight:

- Comparable to wooden bundles

Advantages

- Very high mechanical strength

- Suitable for all stone types (marble, travertine, limestone, granite, etc.)

- Safe for transport by trailer and container

- Excellent protection over long-distance routes

Packing Process

- All steel members are tightened and locked from the top with longitudinal bolts

- Corners are protected with EPS or cardboard angle protectors

- Final wrapping is done with industrial shrink film or stretch film to stabilize the load

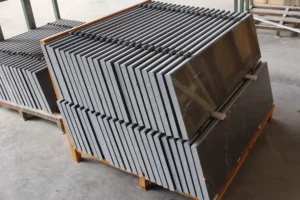

Iron Pallet

Iron Pallet

Iron pallets are a custom, heavy-duty solution for packing thick tiles and heavy project stones.

Technical Specifications

- Manufactured from steel box sections 40×40 mm or 40×80 mm

- Standard height: 80 mm for forklift access

- High load-bearing capacity for heavy and thick stone tiles

- Designed for export and long-distance transportation

- Recyclable: Yes

Packing Process

- Tiles are precisely stacked on the iron pallet

- The load is secured with steel or plastic strapping

- Final stabilization with stretch film or shrink wrap for safe transport

Jumbo Bag (Industrial Stone Bulk Bag)

Jumbo Bag (Industrial Stone Bulk Bag)

Jumbo bags are a strong and economical packaging option for river stones, crushed stones, stone mulch, and other bulk products.

Material

- Woven PP (Polypropylene):

- High tear resistance

- Moisture-resistant

- Suitable for heavy loads

Technical Specifications

- Load capacity: 1.0 to 1.5 tons

- Standard dimensions: 1 m × 1 m

- Equipped with reinforced lifting loops for forklifts and cranes

- Recyclable: Yes

Advantages

- Very fast loading and unloading

- Ideal for irregular and bulk stone sizes

- Widely used in Middle Eastern and European markets

- Resistant to harsh outdoor conditions (rain, dust, etc.)

- Cost-effective and export-friendly

Plastic Bag (Industrial Plastic Sack)

Plastic Bag (Industrial Plastic Sack)

Industrial plastic bags are an economical and versatile packaging solution for light river stones, small crushed stones, and brick units.

Applications

- Small-size river stones

- Light crushed stones

- Brick packs: every 10 bricks can be bundled with plastic shrink wrap

- Suitable for retail, project supply, and export shipments

Technical Specifications

- Typical weight per bag: 30–40 kg (depending on stone type and size)

- Material: reinforced PE / LDPE plastic, tear-resistant and moisture-resistant

- Adjustable dimensions according to product volume and weight

- Recyclable: Yes

Benefits

- Cost-effective packaging format

- Easy to handle and carry by one person

- Adequate protection for light and medium-weight products

- Easy stacking on pallets

- Option to shrink-wrap grouped bags for higher stability

Packing Process

- Bags are filled to a standard weight of 30–40 kg.

- The top of the bag is sealed by heat sealing or mechanical pressing.

- Bags can be placed on wooden or iron pallets, or loaded directly if required.

- For bricks: packs of 10 units are shrink-wrapped with transparent plastic.

- For export shipments: pallets are stretch-wrapped and strapped to prevent movement during transport.

Main Stages of Slab Packaging for Export

- Choosing the Right Bundle Type

Custom-made metal bundles are commonly used for slab packaging. These should be designed to fit the exact dimensions of the slabs and must be constructed from durable materials to prevent breakage during transport. - Foam and Bubble Wrap

To avoid damage during handling, soft foam sheets or bubble wrap are placed between slabs. These layers prevent direct contact between stone surfaces and reduce the risk of scratching or cracking. - Plastic Sheets and Shrink Wrapping

After the slabs are securely placed in the metal bundle, a thick stretch film is wrapped around the load. Then, heat-based shrink wrapping is applied to seal the bundle completely and protect it from dust and moisture. - Professional Strapping

To ensure the slabs remain stable within the pallet, strong plastic straps are applied. These straps hold the slabs firmly in place, preventing any sliding or collision during loading and transit.

Loading and Transport Principles for Exported Slabs

- Slabs should be loaded inside containers with full alignment and standard spacing.

- Transit is usually done via land or sea routes, followed by shipping or cross-border transport to the final destination.

Packaging Types for Different Stone Products

Product Type | Packaging Method |

Slabs | Metal bundle + foam + plastic sheet + strap + shrink wrap |

Tiles (60×60 & 30×60) | Treated wooden pallet + foam + shrink wrap |

Countertops | Wooden crate + plastic layer between surfaces + scratch-proof wrapping |

Custom Stone Artifacts | Wooden crate + foam + plastic or metal strap |

Final Note: Packaging Quality Assurance at Karimi Stone

At Karimi Stone, we ensure the highest safety and quality in stone packaging using top-grade materials, custom-designed metal bundles and wooden pallets, and advanced shrink wrapping and strapping techniques. Our mission is to guarantee the secure delivery of your goods across international routes and the complete satisfaction of our global clients.